|

Orton

Model SP-4A Series Molten Glass Viscometers

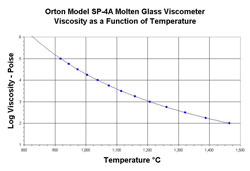

are designed to measure the viscosities of glasses at various

temperatures for ASTM C-965 Procedure A and ISO 7884/2

testing. The Model SP-4A is used to measure viscosities at

specific temperarures in order to generate a curve of the

viscoelastic behavior of molten glass, as shown in the graph

to the right.

Custom Systems

Model SP-4A-CC |

To

make testing cost effective, Orton designs the system

to accommodate your platinum crucible size. The

systems in the photographs are examples of units that

were designed specifically for the customer's sample

crucible size requirements.

The photo to the left is a 1,500¡ÆC, laboratory bench

top system using a platinum crucible approximately 74

mm (2.9¡±) tall with a top OD of 68 mm (2.7¡±) which

contains approximately 300 grams of glass.

The photo to the right is a 1,500¡ÆC, glove box system

using a platinum crucible approximately 64 mm

(2.50¡±) tall by 22 mm (0.865¡±) OD, which contains

less than approximately 10 grams of glass. |

Model SP-4A-GB

Model SP-4A-GB |

The Model SP-4A

System includes vertical tube furnace (molybdenum disilicide,

platinum, or silicon carbide heating elements), a type ¡°S¡±

furnace control thermocouple, a temperature control system

with a multi-segment user programmable PID controller,

stepdown transformer (if required), a crucible support

pedestal, a type ¡°S¡± sample thermocouple, a Brookfield

viscometer, and component support structure.

The crucible is loaded into the system in one of three ways.

First, the crucible is placed on a fixed pedestal support, and

the furnace is lowered over the crucible. Second, the crucible

is placed on the moveable support pedistal, and the pedestal

is raised into the fixed position furnace. And third, the

crucible is manually lowered into the fixed position furnace

and rests on the fixed position pedestal support. The pedestal

or furnace movements can be manual or motorized.

The crucible is loaded into the system in one of three ways.

First, the crucible is placed on a fixed pedestal support, and

the furnace is lowered over the crucible. Second, the crucible

is placed on the moveable support pedistal, and the pedestal

is raised into the fixed position furnace. And third, the

crucible is manually lowered into the fixed position furnace

and rests on the fixed position pedestal support. The pedestal

or furnace movements can be manual or motorized.

It is necessary to lower and raise the spindle into and out of

the molten glass in the crucible. The viscometer is supported

above the furnace, and is normally raised and lowered

manually, but can be motorized.

The entire system is designed around the purchaser¡¯s

crucible size, range of viscosities, component movement

method, and budgetary constraints.

The crucible and spindle can be supplied by Orton, however,

since most glass companies have access to lower cost platinum,

most users provide their own crucibles and spindles.

| Model

SP-4A Series Specifications |

| Sample

Size |

20

to 300 grams, or larger |

| Crucible

Size |

per

customer specifications |

| Maximum

Temperature |

1,500¡ÆC

Standard (1,600¡ÆC available) |

| Heating

Element |

Molybdenum

Disilicide, Silicon Carbide, Platinum |

| Temperature

Control System |

Multi-segment

PID - Automatic |

| Rotational

Viscometer |

Brookfield

Series to suit |

| Viscometer

Spindle |

Design

to suit crucible |

| Power

Requirements |

120

VAC, 10 amp, 50/60 Hz (240 VAC available) |

| Dimensions |

Dimensions

as required |

*Descriptions

and specifications are subject to change without notice.

|