|

Thermal Dilatometric

Analysis (TDA), often called "dilatometry", measures

the dimensional change of a material (ceramics, glasses, metals,

composites, carbon/graphite, minerals, polymers, and others) as a

function of temperature. This test determines both reversible and

irreversible changes in length (expansion and shrinkage) during

heating and cooling, and pinpoints where reactions occur that cause

expansion or contraction. Samples are quickly and easily measured for

determining firing ranges and firing schedules, measuring thermal

expansion ranges for glaze fits, and measuring thermal expansion

ranges for R&D, QC or product certification. Orton dilatometers

are used for ASTM E-228 testing.

A. Characteristics or

Properties Measured

Coefficient of Thermal Expansion (CTE),

softening point, glass transition temperature, curie point,

crystalline transformation, phase transition, shrinkage, warping,

bloating, sintering rate, isothermal creep, stress relaxation.

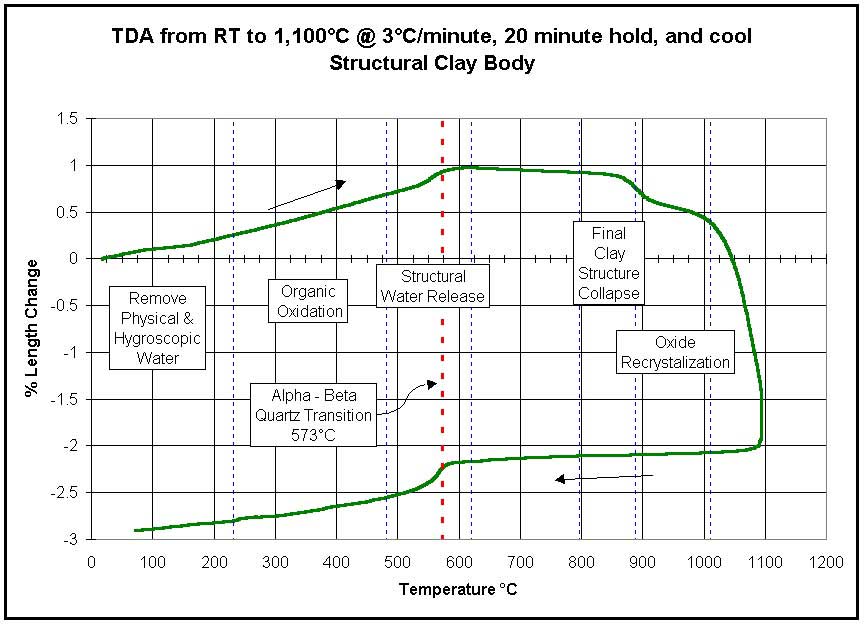

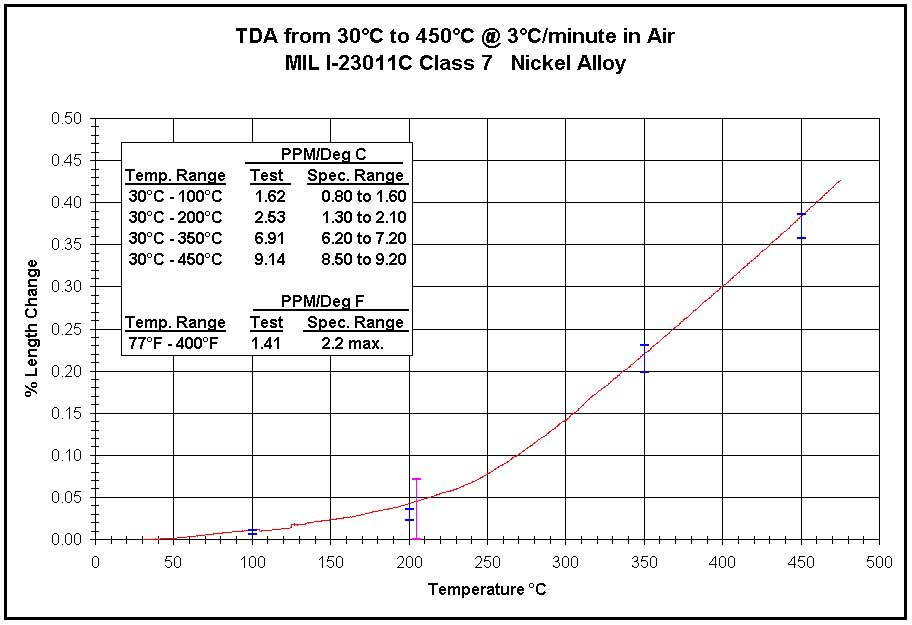

The test results are a graph of the TDA signal (converted to percent

length change) on the Y-axis plotted versus the sample temperature in

¡ÆC on the X-axis. Sample graphs of enhanced output are shown below.

| Examples of

Applications |

Ceramics - ASTM E-228 |

Metals MIL I-23011C Class 7 |

| Range of TDA Test Conditions: |

- -150¡ÆC to +1,600¡ÆC

- Ambient, Inert, Reducing Atmospheres

- Simple Heat-up and Cool-down, Iso-thermal Holds,

Programmed Thermal Cycles

|

B. Standard Dilatometers

| Standard,

Single Sample, Horizontal Dilatometers |

|

DIL

2010 B |

DIL

2010 C |

DIL

2010 STD |

DIL

2012 STD |

DIL

2016 STD |

| Temperature Range |

RT to 1,000¡ÆC |

RT to 1,000¡ÆC or

-170¡ÆC to +300¡ÆC |

RT to 1,000¡ÆC |

RT to 1,200¡ÆC |

RT to 1,600¡ÆC |

| Furnace |

Kanthal - Tube |

Nichrome - Split Shell

Cryogenic Chamber |

Kanthal - Tube |

Kanthal - Tube |

Silicon Carbide - Tube |

| Thermocouple |

Type "N" |

Type "N" |

Type "S" |

Type "S" |

Type "S" |

| Sample Holder and Probe Rod |

Fused Quartz |

Fused Quartz |

Fused Quartz |

High Alumina |

High Alumina |

| Sample Size (max) |

50 mm long by

20 mm diameter |

100 mm long by

10 mm diameter |

100 mm long by

20 mm diameter |

50 mm long by

20 mm diameter |

50 mm long by

20 mm diameter |

| Contact Load |

113 grams |

Adjustable

4 grams min. |

Adjustable

4 grams min. |

Adjustable

4 grams min. |

Adjustable

4 grams min. |

| Temperature

Control |

Orton

Multi-segment Controller |

| Data Acquisition |

Orton

On-board Computer |

| Data Analysis |

Orton

Analysis Software (Windows 95/98/2000 Based) |

| Computer

Interface |

RS232

Cable |

| Controlled

Atmosphere Option |

Not

Available |

Yes |

Yes |

Yes |

Yes |

| Power

Requirements |

120

VAC, 15 amp, 50/60 Hz |

120

VAC, 15 amp, 50/60 Hz |

120

VAC, 15 amp, 50/60 Hz |

120

VAC, 15 amp, 50/60 Hz |

240

VAC, 205 amp, 50/60 Hz |

*Descriptions and specifications are subject to

change without notice.

¡¡

|

Other Orton Dilatometers

• Vertical

• 2 Sample

• Multiple Sample

• Non-contact Laser

• Rapid turnaround

• Quench (metallurgical)

|

|

Contact Orton for more

details.

C. Computer Analysis

Every Orton dilatometer is supplied

with the software to add to the user's PC in order to acquire, save

and analyze the data generated by the dilatometer. The Orton

Dilatometer Software is a Visual Basic executable routine written for

Windows 95/98/2000 based personal computers. It can be used to monitor

the dilatometer test in real time, or can be used to examine the test

data after the run. The software imports the data through the RS232

interface, and stores it on the hard drive for immediate or

post-testing analysis. The software enables the user to:

View the dilatometer data in a variety of

presentations

- percent linear change (PLC) vs.

temperature

- percent linear change (PLC) vs. time

- first derivative of the percent linear

change (DCE) vs. temperature

- first derivative of the percent linear

change (DCE) vs. time

- percent linear change (PLC) and first

derivative of the percent linear change (DCE) vs. temperature

- percent linear change (PLC) and first

derivative of the percent linear change (DCE) vs. time

Perform a variety of analyses

- calculate the coefficient of thermal

expansion (CTE) between specified temperatures, or a series of

specified temperatures

- calculate the average coefficient of

thermal expansion from room temperature to a specified temperature

at a specified temperature increment

- determine transition temperature

- determine softening temperature

- locate alpha-beta quartz transition

Export the data in a text file format for independent analysis or

archiving purposes

D. Additional

Information on TDA

All materials expand and contract as a function

of temperature. For two materials to adhere to each other, such as

glass to metal seals, metalizations to substrates, and glazes to

bodies, their respective thermal expansion characteristics must be

known, matched, and controlled. Thermal Dilatometric Analysis (TDA),

often called Dilatometry, measures the amount of dimensional change of

a material (ceramics, glasses, metals, composites, carbon/graphite,

minerals, plastics, and others) during a controlled thermal cycle.

Dilatometry measures the normal expansion and contraction of a

material, including its reversible phase changes. This procedure also

measures the irreversible changes in length that are the result of

decompositions, phase transformations, and other chemical reactions,

and helps identify the temperature ranges of those events and

reactions. Such testing is helpful when trying to control the thermal

expansion characteristics of various lots of materials, and in

determining drying and firing schedules.

| Principle of Operation |

|

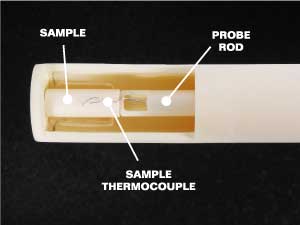

The sketch above shows the concepts of a

dilatometer. A sample specimen is placed between the end of the sample

holder and the end of the movable probe rod, and the furnace is heated

according to a pre-programmed thermal cycle. As the sample temperature

changes (as recorded by the sample thermocouple), the sample expands

(pushing against the probe rod) or shrinks (pulling away from the

probe rod). The probe rod transmits the amount of sample movement to

an electronic displacement sensor located outside of the heated

chamber. The displacement sensor generates an electronic signal

corresponding to the positive or negative change in sample length and

continuously sends the signal to the computer. The computer converts

the signal to the percent of length change (%DL) and saves it along

with the elapsed time and the sample temperature. The basic TDA curve

is generated by plotting the percent of length change (%DL) on the

Y-axis against the sample temperature.

| Horizontal

Dilatometer |

|

|

The photos above are a horizontal

dilatometer with the furnace moved away to expose the sample holder,

and a close-up view of the sample holder. The photo on the right shows

how the sample is positioned between the end of the sample holder and

the probe rod. After positioning the sample in the sample holder, the

furnace is moved horizontally to surround the sample and sample

holder.

The probe rod extends from the end of the

sample, throught the sample holder tube, and connects to the

displacement sensor assembly outside the furnace. The probe rod is

spring loaded outside the furnace to keep it in constant contact with

the sample, even when shrinking.

The main advantage of the horizontal system

is the uniform temperature zone for the sample. Most dilatometer tests

are performed with a horizontal unit.

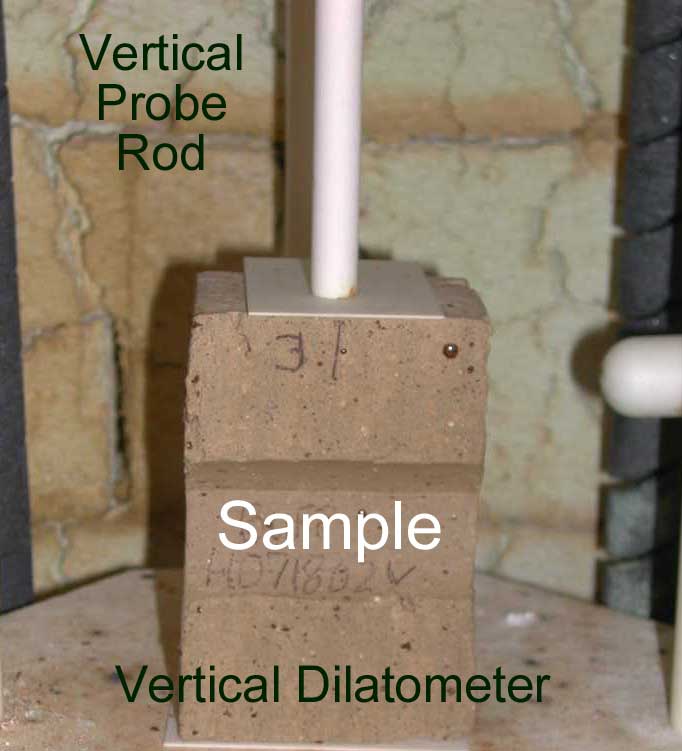

Vertical Dilatometer

For larger samples, such as structural clay

bodies, a vertical  dilatometer

is used. The sample is placed into the furnace and the vertical probe

rod is lowered to contact the sample (as shown in the photo at the

right). The furnace is heated according to the pre-programmed thermal

cycle. As the sample temperature changes, the sample expands, pushing

up on the probe rod, or shrinks, pulling away from the probe rod. The

probe rod is vertically suspended and counterweighted so that gravity

keeps it in constant contact with the sample. The probe rod transmits

the amount of sample movement to the electronic displacement sensor

located overhead and outside the furnace. dilatometer

is used. The sample is placed into the furnace and the vertical probe

rod is lowered to contact the sample (as shown in the photo at the

right). The furnace is heated according to the pre-programmed thermal

cycle. As the sample temperature changes, the sample expands, pushing

up on the probe rod, or shrinks, pulling away from the probe rod. The

probe rod is vertically suspended and counterweighted so that gravity

keeps it in constant contact with the sample. The probe rod transmits

the amount of sample movement to the electronic displacement sensor

located overhead and outside the furnace.

E. Frequently Asked Questions:

Percent Length Change (PLC)

and Coefficient of Thermal Expansion (CTE): Percent Linear

Change (PLC) is the amount of expansion or shrinkage expresses in

percentage of an initial length. A standard TDA curve is usually the

PLC on the Y-axis and the temperature on the X-axis. The thick, black

line in the graph below is a typical TDA curve of glass.

Temperature: The temperature range for a

dilatometer is determined by the type of heating element or heating

system used. The standard Orton dilatometers are made for one of the

following temperature ranges:

- -170¡ÆC to +300¡ÆC (Cryogenic cooling

chamber and Ni-chrome Heating Element with Fused Quartz Sample

Holder and Probe Rod)

- Room Temperature to 1,000¡ÆC (Kanthal

Heating Element with Fused Quartz Sample Holder and Probe Rod)

- Room Temperature to 1,200¡ÆC (Kanthal

Heating Element with High Alumina Sample Holder and Probe Rod)

- Room Temperature to 1,600¡ÆC (Silicon

Carbide or Platinum Heating Element with High Alumina Sample

Holder and Probe Rod)

- Room Temperature to 1,700¡ÆC

(Molybdenum Disilicide Heating Element with High Alumina Sample

Holder and Probe Rod)

Thermal Cycle: The

most commonly used thermal cycle for dilatometry is a simple,

controlled heat-up rate of 3¡ÆC per minute from ambient temperature to

the maximum temperature, then the test is terminated. For testing

materials that experience irreversible reactions or when quartz

transitions are critical, the thermal cycle can be extended to include

a cool down segment. For developing firing schedules or examining what

happens during a certain firing schedule, the dilatometer can be

programmed to follow an actual production schedule that contains

multiple ramps and soaks. The Orton dilatometer can be programmed for

simple cycles, or up to a 20 segment thermal cycle.

Heat-up Rate: A

sample does not absorb heat instantaneously, so it does not expand or

shrink instantaneously. Since a finite amount of time is required for

a sample to come to an equilibrium temperature and expansion/shrinkage

condition, some thermal expansion measurements are made by holding the

furnace temperature constant until the sample reaches an equilibrium

temperature and length. These static condition (isothermal) tests take

a lot of time, and are generally performed at only a few temperatures.

¡¤ To save time and generate more information over a broader range of

temperatures, most thermal expansion measurements are taken while the

sample is being heated during a dynamic heat up. The thermal

conductivity, size, and geometry of the sample will influence how

quickly the sample can absorb heat and change length. With fast heat

up rates, there is a tendency for the sample temperature to lag behind

the furnace temperature, and the corresponding change in length to lag

as well. With slow heat up rates, the amount of thermal lag and length

change lag are much less, but the tests can be very long. Over the

years the common industrial practice has evolved to a compromise rate

of 3¡ÆC per minute. This keeps the amount of lag to a minimum and the

testing time practical. ¡¤ The important factor is to be consistent in

the heat up rate used, and to be consistent with the sample size and

geometry.

Sample Size:

The maximum sample size for the horizontal dilatometer is 2" long

by 3/8" diameter or square. Samples longer than 2" will

extend beyond the isothermal zone, and larger diameter samples will

not fit into the sample holder. The ends of samples must be flat,

parallel, and perpendicular to the length axis. ¡¤ The ultimate sample

length depends upon the total amount of expansion or the total amount

of shrinkage expected. The displacement sensor on the standard Orton

dilatometer has a total linear movement of 5.0 millimeters (0.200

inches). Orton prefers to use only the center half of this range, so

total sample movement (expansion or shrinkage) is 2.5 millimeters

(0.100 inches). Consequently, low expansion/shrinkage samples should

be long, and high expansion/shrinkage samples can be shorter. The

following table shows the maximum percent expansion / shrinkage of

different length samples.

|

Sample Length

millimeters

|

Sample Length

inches

|

Percent

Expansion/Shrinkage

|

|

5

10

15

20

25

30

35

40

45

50

|

0.197

0.394

0.591

0.787

0.984

1.181

1.378

1.575

1.772

1.969

|

50.00%

25.00%

16.67%

12.50%

10.00%

8.33%

7.14%

6.25%

5.56%

5.00%

|

Sensitivity: (To be added later)

Atmospheres: Tests

are normally performed in ambient air. By adding the controlled

atmosphere option to the Orton dilatometer, inert and reducing

atmospheres, as well as vacuums are possible. There are several

concerns when running tests in controlled atmospheres:

- The atmosphere tube surrounding the

sample is a thermal barrier, and creates a larger thermal lag

between the heating elements and the sample. Faster heating rates

create an even larger thermal lag. Slower heating rates may be

desirable.

- Flowing a gas over the sample will cool

the sample, and create an even greater thermal lag between the

sample and the heating elements. Flow rates should be a low as

possible to minimize this affect.

- Reducing atmospheres, such as hydrogen,

will significantly degrade platinum thermocouples at elevated

temperatures. Small amounts of moisture with the hydrogen will

increase the rate of platinum degradation. Using "dry"

hydrogen will reduce the moisture attack. Using a surrogate gas,

such as dry helium, may be reducing enough, and will retard

platinum deterioration. A last alternative is to use a shielded

thermocouple to totally avoid platinum degradation. However, a

shielded thermocouple introduces another thermal lag into the

test.

- A vacuum is an excellent thermal

barrier to heat transfer. There is no gas for conduction and

convection. Radiation does not become an effective heat transfer

mechanism until elevated temperatures.

¡¡ |