Simultaneous DTA/TGA

|

The

Orton Simultaneous DTA/TGA is a powerful

thermoanalytical technique that combines a DTA and a

TGA into one instrument that performs both DTA and TGA

on the same sample at the same time. This instrument

or testing technique is sometimes referred to as

Simultaneous Thermal Analysis, or STA, or simply ST.

The resulting DTA and TGA curves are simultaneously

plotted on a dual Y-axis graph so the DTA¡¯s

fingerprint and the TGA¡¯s weigh loss/gain

characteristics are directly compared as the test

sample is heated and cooled.

The

photo at the right is the Model ST-730 series

simultaneous DTA/TGA System which includes the

furnace, differential thermocouple, analytical

balance, and furnace control console with

user-programmable controller. Although not shown, the

system includes Windows 98/2000 compatible data

acquisition/analysis software and an analog to digital

interface card for the user supplied personal computer

system.

|

|

A.

Characteristics or Properties Measured

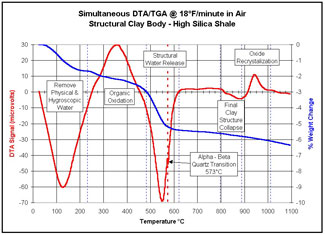

The DTA

identifies the temperature regions and the magnitude of

critical events during a drying or firing process such as

drying, binder burnout, carbon oxidation, sulfur oxidation,

structural clay collapse, cristobalite transitions, alpha-beta

quartz transitions, carbonate decompositions,

recrystallizations and melting.

The TGA

measures the weight loss of a material from a simple process

such as drying, or from more complex chemical reactions that

liberate gases, such as structural water release, structural

decomposition, carbonate decomposition, sulfur oxidation, and

fluoride oxidation. The TGA also measures the weight gain of a

material from a simple process such as re-hydration, or from

more complex surface reactions from reactive gas atmospheres.

Examples

of Applications

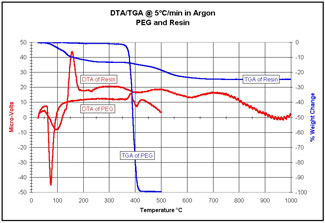

The test results are a dual Y-axis graph of the DTA signal (microvolts)

on one Y-axis and the TGA signal (actual weight loss or gain

converted to percent weight loss) on the other Y-axis plotted

versus the sample temperature on the X-axis. Sample graphs of

enhanced standard outputs are shown below.

| Ceramics -

Structural Clay Analysis |

Ceramics - Body

and Binder Studies |

|

|

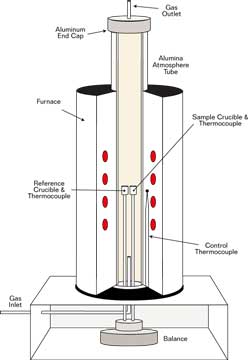

Principle of

Operation

| The

standard Orton Simultaneous DTA/TGA uses a pan

balance, in which the sample and reference cups are

supported by a pair of vertical thermocouples

(differential thermocouple) positioned on the balance

load cell (concept sketch below). |

|

|

After both cups are

placed on top of the differential thermocouple stalks,

the furnace is lowered over the cups, the balance is

zeroed, and the furnace is heated and cooled according

to the programmed thermal cycle. The differential

thermocouple output (DTA signal) and balance output (TGA

signal) are continuously recorded, displayed on a PC

monitor, and stored on the PC for post testing

analysis. |

B.

Standard Simultaneous DTA/TGA Instruments from Orton

The standard

Orton Simultaneous DTA/TGA uses one of two pan balances with

different sensitivity ranges, and an appropriate furnace for

the desired temperature range.

| Model

Number Series |

ST-730 |

ST-740 |

|

| Room

Temperature to 1,200¡ÆC |

ST-732 |

ST-742 |

| Room

Temperature to 1,600¡ÆC |

ST-736 |

ST-746 |

| Sample

Volume (cubic millimeters) |

150 |

150 |

| Sample

Size (grams)* |

up to

0.350 |

up to

0.350 |

| Sample

Cup Material |

High

Alumina |

High

Alumina |

| Sample

Cup Design |

Boersma |

Boersma |

| Differential

Thermocouple |

Type

¡°S¡± |

Type

¡°S¡± |

| DTA

Sensitivity (micro-volts) |

<

0.0005 |

<

0.0005 |

| Atmospheres |

Air,

Argon, Nitrogen |

Air,

Argon, Nitrogen |

| Range of Sample

Weight Change |

5 to 33% |

2 to 20% |

| Balance

Sensitivity (micro-grams) |

100 |

10 |

| Electric Power |

120 VAC, 15 amp,

50/60 Hz |

120 VAC, 15 amp,

50/60 Hz |

| Cooling

water to open drain |

<1

gallon/minute |

<1

gallon/minute |

Note:

assume a material with a green specific gravity of 2.35 g/cc

¡¡

Sample

Size

The Orton Simultaneous DTA/TGA instruments have been

specifically designed for ceramics and other materials that

require sample sizes larger than DSC¡¯s to insure sample

homogeneity.

Temperature

Ranges / Furnace Type

Room Temperature to 1,200¡ÆC

Kanthal wire wound heating element

Room Temperature to 1,600¡ÆC

Platinum alloy wire wound heating element

Heating

Rates / Thermal Cycle

DTA¡¯s are generally performed with

fast heat up rates, and TGA¡¯s are generally performed with

slow heat up rates. Since both tests are performed at the same

time with the simultaneous unit, a compromise heat up rate

must be used. A typical simultaneous DTA/TGA heat up rate for

ceramic materials is 10¡ÆC per minute. Other rates are

possible by simply changing the thermal cycle on the

system¡¯s PID furnace controller.

Most ST tests

are performed at a standard heating rate to the maximum

temperature, then discontinued. With the Orton systems, the

thermal cycle can be extended to include the cooling data. In

addition, other programmed cycles that contain multiple ramps

and soaks, such as actual production drying or firing

schedules, are possible.

Computer

Analysis

All Orton ST's are supplied with data

acquisition and analysis software for the user's PC. The

software displays the test progress on the monitor, stores the

data and enables the user to perform the standard DTA and TGA

analysis on the data.

Atmospheres

The Orton Model ST-730/740 series

systems are designed for standard ceramic applications. The

Model ST-730/740 series systems are equipped with an

atmosphere port and simple control flow valve for flowing air,

argon, or nitrogen through the testing chamber. To keep

manufacturing costs down and to keep operation simple, these

Orton systems are not sealed for vacuums, corrosive

atmospheres, or ultra low oxygen content atmospheres. Other

Orton systems are designed for controlled atmosphere

operation.

¡¡

C.

High Performance DTA/TGA Systems

For low

weight change testing, a more sensitive, higher precision

balance is required. Orton uses an overhead, continuous

recording electro-balance for these applications.

For controlled

atmosphere testing, a sealed balance and heating chamber

is required. Orton uses a sealed, overhead, continuous

recording electro-balance with a sealed heating chamber for

these applications.

A true

simultaneous DTA/TGA is a system in which the same

sample is used for both weight loss (TGA) and energy change (DTA)

measurements. Whenever an overhead balance is used in a true

simultaneous DTA/TGA, the mechanical fixturing required to

suspend the two sample cups plus their buried thermocouples

without impacting free movement of the balance becomes more

sophisticated. Sample loading and maintenance is more

complicated as a result. Orton has simplified the mechanical

arrangement, made sample loading and unloading easier, and

reduced the maintenance costs by manufacturing a Concurrent

DTA/TGA.

Concurrent

DTA/TGA

|

A

Concurrent DTA/TGA places two samples inside the same

heated chamber for simultaneous testing. One sample is

used for the DTA, and the other is used for the TGA.

The two DTA thermocouple stalks and cups are inserted

into the heated chamber from the bottom and are

position immediately next to the TGA sample cup which

is suspended from the overhead electro-balance. The

DTA system is mechanically independent from the

extremely sensitive analytical balance system, greatly

simplifying the mechanical arrangement. Since both

samples are in immediate proximity they are

experiencing identical thermal and atmosphere

conditions, so there is no compromise on the quality

of the data generated.

The

Concurrent DTA/TGA is an ideal system for advanced

research applications where weight losses (or gains)

are small, or when vacuums or aggressive atmospheres

are required.

|

|

Concurrent DTA/TGA

Models

|

Model

Number Series

|

CST-720-1000

|

CST-720-2000

|

|

|

Room

Temperature to 1,200 ¡ÆC

|

CST-722-1000

|

CST-722-2000

|

|

Room

Temperature to 1,600 ¡ÆC

|

CST-726-1000

|

CST-726-2000

|

|

DTA

Sample Volume (cubic millimeters)

|

150

|

150

|

|

DTA

Sample Size (grams)*

|

0.350

|

0.350

|

|

DTA

Sample Cup Material

|

High

Alumina

|

High

Alumina

|

|

DTA

Cup Design

|

Boersma

|

Boersma

|

|

Differential

Thermocouple

|

Type

¡°S¡±

|

Type

¡°S¡±

|

|

DTA

Sensitivity (micro-volts)

|

<

0.0005

|

<

0.0005

|

|

TGA

Sample Size (grams)*

|

0.100

|

0.100

|

|

TGA

Sample Cup Material

|

Platinum

|

Platinum

|

|

Range

of Sample Weight Change

|

0

to 100%

|

0

to 100%

|

|

Weight

Change Range (grams)

|

0.000

to 0.350

|

0.000

to 0.350

|

|

Balance

Capacity (grams)

|

100

|

3.500

|

|

Max.

Balance Change Capacity (grams)

|

10

|

0.150

/ 0.750

|

|

Balance

Sensitivity (micro-grams)

|

1.0

|

0.1

|

|

%

Sensitivity Range

|

<

0.0003%

|

<

0.0000%

|

|

Atmospheres

/ Vacuum

|

Yes

|

Yes

|

| Electric Power |

120 VAC, 15 amp, 50/60 Hz

|

120 VAC, 15 amp, 50/60 Hz

|

| Cooling water

to open drain |

<1 gallon/minute

|

<1 gallon/minute

|

*

Note: assume a material with a green specific gravity of 2.35

g/cc

|