|

Thermal

Gravimetric Analysis (TGA) is a simple analytical technique

that measures the weight loss (or weight gain) of a material

as a function of temperature. As materials are heated, they

can loose weight from a simple process such as drying, or from

chemical reactions that liberate gasses. Some materials can

gain weight by reacting with the atmosphere in the testing

environment. Since weight loss and gain are disruptive

processes to the sample material or batch, knowledge of the

magnitude and temperature range of those reactions are

necessary in order to design adequate thermal ramps and holds

during those critical reaction periods.

A.

Characteristics or Properties Measured

Drying, structural water release, structural decomposition,

carbonate decomposition, gas evolution, sulfur oxidation,

fluoride oxidation, and re-hydration.

Examples of

Applications

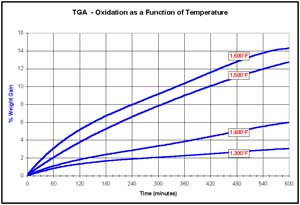

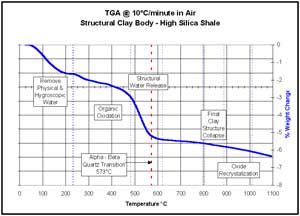

The test results are a graph of the TGA signal (actual weight

loss or gain converted to percent weight loss) on the Y-axis

plotted versus the sample temperature in ¡ÆC on the X-axis.

Sample graphs of enhanced standard outputs are shown below.

| Structural

Clay Analysis |

Advanced

Ceramics-Oxidation Studies |

|

|

TGA

- Principle of Operation

A sample of the test material is placed into a high alumina

cup that is supported on, or suspended from an analytical

balance located outside the furnace chamber. The balance is

zeroed, and the sample cup is heated according to a

predetermined thermal cycle. The balance sends the weight

signal to the computer for storage, along with the sample

temperature and the elapsed time. The TGA curve plots the TGA

signal, converted to percent weight change on the Y-axis

against the reference material temperature on the X-axis.

Orton

manufactures two basic types of TGA instruments. One uses a

standard pan balance in which the sample cup is supported by a

ceramic post sitting on the balance pan (sketch below left),

and the other uses a higher resolution balance that suspends

the sample cup from overhead (sketch below right).

¡¡

B.

Standard TGA Instruments from Orton

Model TG-730 Series |

Model TG-740 Series |

Model TG-720 Series |

Temperature

Ranges

There are three temperature ranges and four types of furnaces

for those ranges:

- Room Temperature to 1,200¡ÆC

Kanthal wire wound heating element

- Room Temperature to 1,600¡ÆC

Platinum alloy wire wound heating element Silicon Carbide

heating element

- Room Temperature to 1,700¡ÆC

Molybdenum Disilicide heating elements

Type

of Balance

There are four balances used in standard Orton systems. These

balances have been selected based upon the combination of

sample size and weight loss/gain that are typical for most

ceramic material requirements.

| Model

Number Series |

TG-

730

|

TG-740

|

TG-720-1000

|

TG-720-2000a

|

TG-720-2000b

|

| Sample

Volume (cubic millimeters) |

150

|

150

|

150

|

150

|

150

|

| Sample

Size (grams)* |

0.350

|

0.350

|

0.350

|

0.350

|

0.350

|

| Range

of % Weight Change |

5

to 33%

|

2

to 20%

|

0

to 100%

|

0

to 100%

|

0

to 100%

|

| Max.

Weight Change (grams) |

0.116

|

0.070

|

0.350

|

0.350

|

0.350

|

| Min.

Weight Change (grams) |

0.018

|

0.007

|

0.000

|

0.000

|

0.000

|

| Balance

Capacity (grams) |

61

|

42

|

100

|

3.500

|

3.500

|

| Max.

Balance Change Capacity (grams) |

|

|

10

|

0.150

|

0.750

|

| Balance

Sensitivity (grams) |

0.0001000

|

0.0000100

|

0.0000010

|

0.0000001

|

0.0000001

|

| Balance

Sensitivity (micro-grams) |

100.0

|

10.0

|

1.0

|

0.1

|

0.1

|

| %

Sensitivy of Min. Sample Weight Change |

0.5714%

|

0.1429%

|

0.0000%

|

0.0000%

|

0.0000%

|

| %

Sensitivy of Max. Sample Weight Change |

0.0866%

|

0.0143%

|

0.0003%

|

0.0000%

|

0.0000%

|

*

Note: assume a material with a green specific gravity of 2.35

g/cc

Orton has a large

sample option for the TG-730 and TG 740 series balances.

Instead of the 150 cubic millimeter sample cup, a 770 cubic

millimeter cup is available. Other balances and TGA systems

are available for TGA applications requiring even larger

sample sizes, or special samples.

Heating

Rates

Most ceramic samples are normally heated from ambient to the

maximum temperature at 3¡ÆC per minute. Slow heating rates are

preferred so that the weight change can occur over a narrower

time span and temperature range. The resulting curve is

steeper and the onset temperature is closer to the actual.

Fast heating rates spread the weight change over a wider time

span and temperature range, and generate less steep curves and

shift the onset temperature above the actual. Orton control

systems provide the ability to set various heat up rates

according to the user's requirements.

Computer Analysis

All Orton TGA's are supplied with data acquisition and

analysis software for the user's PC. The software displays the

test progress on the monitor, stores the data and enables the

user to perform analysis on the data.

Thermal

Cycle

Most TGA tests are performed at a standard heating rate to the

maximum temperature, then discontinued. The thermal cycle can

be extended to include the cooling data. Other programmed

cycles that contain multiple ramps and soaks, such as actual

production drying or firing schedules, are available.

Atmospheres

For most ceramic materials, TGA tests are normally performed

in ambient air. The TG-730 and TG-740 series TGA's are

designed for ambient air or inert atmosphere operation. The

TG-720 Series are used for other controlled atmospheres,

including vacuums |