|

Differential

Thermal Analysis (DTA) is a "fingerprinting"

technique that provides information on the chemical reactions, phase

transformations, and structural changes that occur in a sample during

a heat-up or a cool-down cycle. The DTA measures the differences in

energies released or absorbed, and the changes in heat capacity of

materials as a function of temperature.

All materials behave in certain, predictable ways when exposed to

certain temperatures, so the resulting DTA curve is an indication of

the materials and phases present in the sample. For example, the DTA

is used to indicate the relative magnitude of reactions and phase

transitions of ceramic materials or batches that can be destructive so

that safe drying and firing schedules can be determined. The DTA

identifies the temperature regions and the magnitude of critical

events during a drying or firing process such as drying, binder

burnout, carbon oxidation, sulfur oxidation,structural clay collapse,

Alpha to Beta quartz transition, carbonate decompositions,

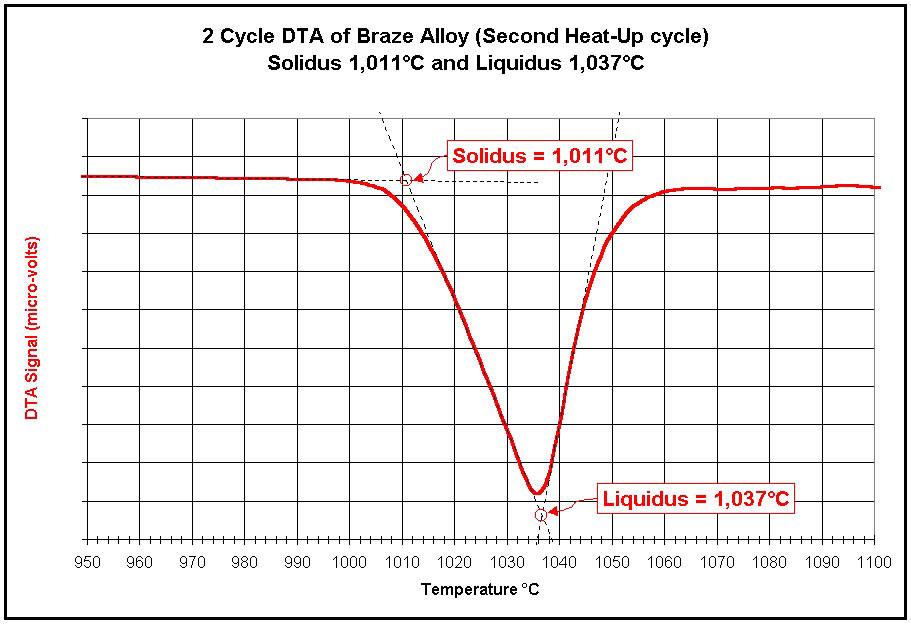

reggcrystalizations, melting and cristobalite transitions. A DTA of a

solder or braze alloy will indicate the solidus and liquidus

temperatures of that alloy.

A. Characteristics or Properties Measured

Drying, decomposition, oxidation, sintering, phase transformation,

devitrification, recrystalization, melting or liquidus temperature,

solidification or solidus temperature, glass transition temperature (Tg),

curie point, energy of reaction, and others.

Examples of Applications

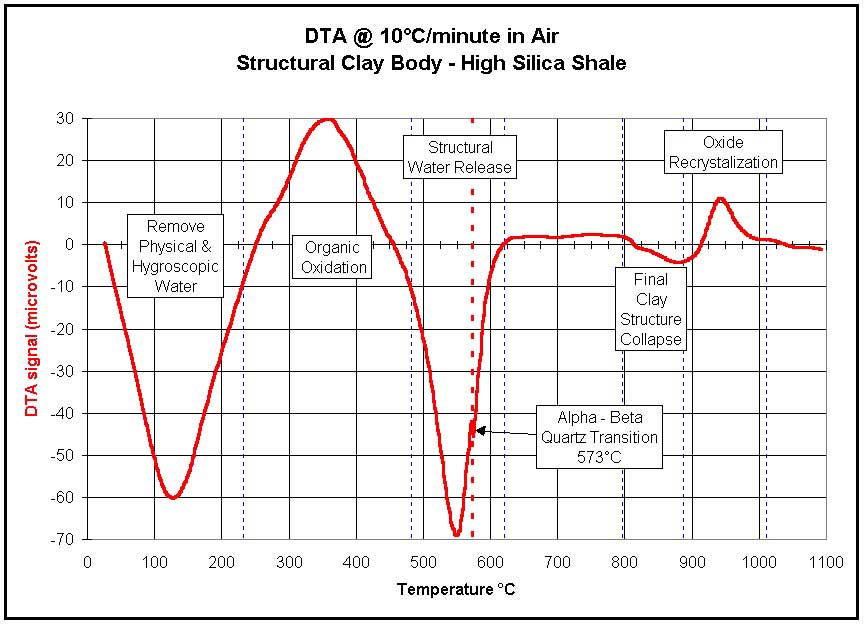

The test results are a graph of the DTA signal (microvolts) on the

Y-axis plotted versus the sample temperature in ¡ÆC on the X-axis.

Sample graphs of enhanced output are shown below.

Ceramics-Clay Analysis |

Metals-Solidus/Liquidus Determinations |

¡¡

| Range of Test Conditions: |

- Room Temperature to +1,600¡ÆC

- Ambient, Inert, and Reducing

Atmospheres

- Simple Heat-up and Cool-down,

Multiple Cycles, and Programmed Thermal Cycles

- Sample Size - 150 mm©ø

|

|

B. Standard Orton DTA Instruments & Specifications

|

|

| |

Model DT-732 |

Model DT-736 |

| Temperature

Range |

20¡ÆC to 1,200¡ÆC |

20¡ÆC to 1,600¡ÆC |

| Sensitivity |

1 micro-volt |

1 micro-volt |

| Differential

Thermocouple |

Type

"S" |

Type

"S" |

| Sample Cup |

Boersma Design,

High Alumina |

Boersma Design,

High Alumina |

| Sample Volume |

10 to 250 mm©ø |

10 to 250 mm©ø |

| Atmospheres |

Air, Inert,

Reducing, Vacuum |

Air, Inert,

Reducing, Vacuum |

| Temperature

Control |

Muli-segment

PID Controller, Phase-angle fired SCR's |

Muli-segment

PID Controller, Phase-angle fired SCR's |

| Power

Requirements |

120 VAC, 15

amp, 50/60Hz (240 VAC avail.) |

120 VAC, 15

amp, 50/60Hz (240 VAC avail.) |

| DTA Module

Dimensions |

18¡± W x 12¡±

D x 25¡± T (460 x 305 x 635 mm) |

18¡± W x 12¡±

D x 25¡± T (460 x 305 x 635 mm) |

| Control Console

Dimensions |

18¡± W x 12¡±

D x 5¡± T (460 x 305 x 130 mm) |

18¡± W x 12¡±

D x 5¡± T (460 x 305 x 130 mm) |

*Descriptions

and specifications are subject to change without notice.

Other sample cup designs

are available. All Orton dilatometers are supplied with data

acquisition and analysis software for computer display, storage and

data analysis.

C. Additional

Information on DTA

| Principle of Operation |

|

DTA measures the

temperature difference between a reference material and the sample

during a heat up or cool down. The temperature difference is an

indication of the type of event that is occurring in the sample, and

its magnitude.

A sample of the test material is placed into a special shape cup so

the test material surrounds a thermocouple bead. The cup is made from

a sintered, high purity alumina, which is relatively inert to the test

sample. An identical cup (the reference cup) is filled with an inert

material (powdered, high purity alumina) and is placed immediately

beside the sample cup. When both cups are uniformly heated at a

constant rate, the increasing temperature must pass through the

materials in the cups in order to raise the temperature of the buried

thermocouple beads. The "DTA signal" is the difference in

temperature between these two thermocouple beads while the sample cups

are heated, and is constantly saved on the computer along with the

temperature inside the reference cup and the elapsed time.

The DTA curve plots the

"DTA signal" in microvolts on the Y-axis  against

the reference material temperature on the X-axis. If nothing is

occurring in the sample material and the reference material (the

reference material has been carefully selected so no reactions or

transitions occur throughout the test temperature range) , the heat

will pass through both materials at the same rate and raise the

temperature of both thermocouple beads at the same rate. The

difference between the two thermocouple temperatures is zero, so a

flat line is generated. against

the reference material temperature on the X-axis. If nothing is

occurring in the sample material and the reference material (the

reference material has been carefully selected so no reactions or

transitions occur throughout the test temperature range) , the heat

will pass through both materials at the same rate and raise the

temperature of both thermocouple beads at the same rate. The

difference between the two thermocouple temperatures is zero, so a

flat line is generated.

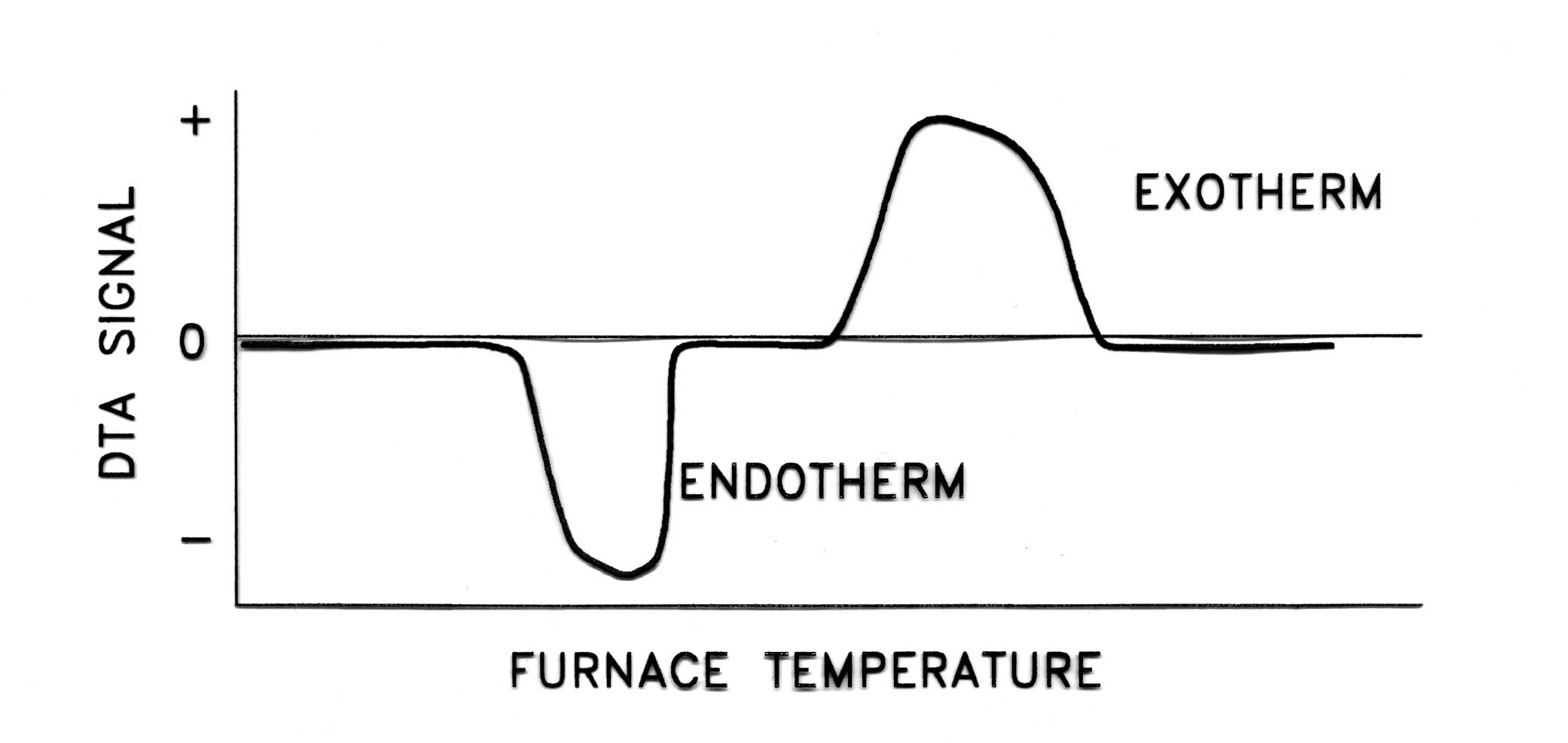

Endothermic Reaction

An endothermic reaction is a chemical reaction that must absorb a

certain amount of energy in order to proceed to completion. When an

endothermic reaction is encountered, the temperature of the material

remains constant while the energy is absorbed. The thermocouple bead

inside the material remains at the same temperature, even though the

temperature outside the cup is rising. Meanwhile, no reactions or

transitions are occurring in the reference material, so the

temperature of the reference material continues to rise. The

differential signal between the sample and reference thermocouples

becomes negative, and the DTA curve drops. Once enough energy is

absorbed and the endothermic reaction is complete, the temperature of

the sample material quickly rises to catch up with the reference

material. The resulting temperature differential reverses back to

zero, and the DTA curve rises back to an equilibrium position. This

endothermic reaction creates a "valley" in the DTA curve.

The depth and breadth of this valley is an indication of the

magnitude, temperature range, and speed of the reaction.

Exothermic Reaction

An exothermic reaction is a chemical reaction that releases a certain

amount of energy upon its completion. When an exothermic reaction is

encountered, the temperature of the material quickly rises above the

outside temperature, and the thermocouple bead inside the material

quickly rises above than the temperature outside the cup. Meanwhile,

no reactions or transitions are occurring in the reference material,

so the temperature of the reference material continues to rise, but

not as fast as the sample material. The differential signal between

the sample and reference thermocouples becomes positive, and the DTA

curve rises. Once the exothermic reaction is complete, the temperature

of the reference material quickly catches up. The resulting

temperature differential reverses back to zero, and the DTA curve

drops back to an equilibrium position. This exothermic reaction

creates a "peak" in the DTA curve. The depth and breadth of

this peak is an indication of the magnitude, temperature range, and

speed of the reaction.

D. Frequently Asked

Questions:

Temperature:

Standard tests range from ambient temperature up to 1,600¡ÆC.

Atmospheres: Tests are normally

performed in ambient air. Inert atmospheres can be used. If reducing

or reactive atmospheres or vacuums are required, the Model DT-720

series DTA is required. See Orton for details.

Thermal Cycle: Most DTA tests are

performed at a standard heating rate to the maximum temperature, then

discontinued. The thermal cycle can be extended to include the cooling

data. Other thermal cycles that contain multiple ramps and soaks, or

multiple cycles (for solidus/liquidus determinations) are easily

programmed by the user with the multi-segment controller that is

supplied with the system as standard.

Heat-up Rate: Most DTA samples are

normally heated from ambient to the maximum temperature at 10¡ÆC per

minute. Other heat-up rates can be used. Faster heating rates are used

to capture reactions that occur quickly. Fast heating rates generate

deeper valleys and higher peaks, and will shift the onset temperature

above the actual. Slower heating rates may miss fast and minor

reactions. Slow heating rates generate shallower valleys and lower

peaks, but will display the onset temperature closer to the actual.

These various heating rates are are easily programmed by the user with

the multi-segment controller that is supplied with the system as

standard.

Sample Size: The sample cup holds

approximately 150 mm©ø of fine powder or liquid.

Sample Cup: The standard sample cup

supplied with the system is a Boersma style cup made from a fine

grained, dense, high purity alumina. A cross section sketch of the cup

is shown in the "Principle of Operation" section above. The

Boersma design allows the sample and reference materials to surround

the thermocouple beads without contacting the beads. This protects the

thermocouple beads from contamination. Orton has other cup designs if

desired. The high alumina was selected due to its non-reactive nature

with most materials at elevated temperaures. If the high alumina is

not a desirable cup material, other materials such as platinum are

available.

Sensitivity: The output of a type

"S" thermocouple at 1,000¡ÆC is 9.587 milli-volts (9,587

micro-volts), and at 1,010¡ÆC is 9.703 milli-volts (9703 micro-volts).

The output difference for only 1¡ÆC is 11.6 milli-volts, or 11.6

micro-volts. With a sensitivity of 1 micro-volt, the DTA with a type

"S" differential thermocouple is capable of discerning a

temperature difference between the sample and reference material of

0.08¡ÆC. For testing temperartures less than 1,200¡ÆC, a type

"K" or type "N" differential thermocouple can be

used for increased sensitivity. The output of a type "K"

thermocouple at 1,000¡ÆC is 41.276 milli-volts (41,276 micro-volts),

and at 1,010¡ÆC is 41.665 milli-volts (41,6653 micro-volts). The

output difference for only 1¡ÆC is 389 milli-volts, or 38.9

micro-volts. With a sensitivity of 1 microvolt, the DTA with a type

"K" or type "N" differential thermocouple is

capable of discerning a temperature difference between the sample and

reference material of 0.025¡ÆC.

DSC versus DTA: See the next section for

a more complete discussion.

| Comparing the DTA versus the DSC |

| DTA |

DSC |

| 1. Provides the same

information as the DSC. |

1. Provides the same

information as the DTA. |

| 2. Larger sample size - for

ceramics and metals that require larger amounts to insure

sample homogeneity. |

2. Small sample size -

ideal for polymers, petrochemicals, pharmaceuticals, etc.

where sample homogeneity is not a concern. Ceramic materials

require averaging the results from several runs to insure

homogeneity. |

| 3. Larger thermal mass

furnaces to insure isothermal conditions for samples, slower

sample turnaround. |

3. Smaller thermal mass

furnaces that provide rapid sample turnaround. |

| 4. Less complicated system,

and lower priced than the DSC. |

4. More sophisticated, more

complex, and more expensive. |

DSC

DTA (Differential Thermal Analysis) and DSC (Differential

Scanning Calorimetry, by the way, there are two versions) are

thermoanalytical techniques that reveal the same information about

materials, but use different methods to determine that information.

They provide the same information on how a specimen ¡°got from here

to there¡± (the chemical reactions, phase and structural changes, and

energies of reactions and changes) during a heatup or cool down cycle.

Although the output traces of the DSC¡¯s and DTA are visually

similar, the operating principles are very different.

The DSC was developed for quickly and automatically analyzing the

energies of reactions of low temperature materials such as polymers,

petrochemicals, and pharmaceuticals. These types of materials are

extremely uniform, so small sample sizes are homogeneous and the

results are reliable. Ceramic materials are not as homogeneous, so

sample sizes that are larger than DSC cups can accommodate are

desired.

There is some confusion concerning DSC¡¯s. Perkin-Elmer markets the

only ¡°power compensated¡± DSC, and is patented. TA, Netzsch, and

others, provide a ¡°heat flux¡± DSC, which is based on the DTA

principle.

DSC (heat flux) is a more sophisticated version of DTA, which measures

the temperature difference between a reference material and the sample

during a heat up or cool down. The temperature difference is an

indication of the type of event that is occurring in the sample, and

its magnitude.

DSC (power compensated) measures the amount of electric energy

required to maintain equal temperatures of the reference material and

sample during a heatup or cool down. The electrical energy required is

an indication of the type of event that is occurring in the sample,

and its magnitude.

For the power compensated DSC there are separate containers for both

sample and reference materials. Each container has its own heating

element and temperature measuring device. The heating element and the

temperature measuring device are discs with imbedded platinum coils

that are separated by a thin electrically insulating wafer.

Temperature is determined by a platinum resistance thermometer (RTD)

which measures the resistance of the platinum as a function of

temperature. The sample and reference chambers are heated equally

until some reaction or change occurs within the sample material. As

the temperature of the sample material infinitesimally deviates from

the reference material temperature, the heat input to one container is

decreased and the heat input to the other container is increased to

maintain a zero temperature difference between the two containers.

This is referred to as a ¡°null balance¡± technique. The quantity of

electrical energy per unit time that is supplied to the heating

elements to maintain this null balance (over and above the normal

thermal schedule) is assumed to be proportional to the heat release

(exothermic reaction) or heat absorbed (endothermic reaction) by the

sample. The DSC curve is expressed in Watts (energy per unit time) as

the Y-axis plotted against the sample temperature as the X-axis.

This power compensated DSC has two control cycle portions. One strives

to maintain the null balance between the sample and reference

material, and the other strives to maintain the desired test heat up

or cool down rate. These processes switch back and forth continuously

to maintain both portions simultaneously.

For rapid cooling, both sample and reference cells are surrounded by a

cooling jacket.

To maintain good thermal contact for rapid system response, the sample

chamber and sample size must be small.

DTA

The DTA is a "passive" system, that is the material is

simply heated and the differential thermocouple output signal is saved

for post testing analysis. For ceramic materials, the DTA is a far

simpler, and less expensive instrument that generates the same

information on a larger sample in one test.

¡¡ |